I suggest a wall clock that's easy to read from anywhere in the garage. Having a clock is a great way to time a task or project or to have some means of knowing when to knock off for the day.

I already had a wall clock hanging around in the house so it got pressed into service in the garage.

I placed it near the door as this was the one place where it could be seen throughout the shop. The lone exception is when I'm sitting at the project workbench, but all I need do is stand up to see the time.

Repurposing the clock cost me a double A battery. It also illustrates the results of beginning scrounging, which is to find stuff I already have that can be used for the need at hand.

Showing posts with label Garage Organization. Show all posts

Showing posts with label Garage Organization. Show all posts

Monday, January 13, 2014

Pegboard's Importance in Organizing the Garage

While buying pegboard usually represents actual cost in setting up a garage, it never hurts to keep an eye out for it when out on scrounging adventures. It pays to know what a sheet retails for in order to avoid paying too much from someone that thinks their stuff is made of gold. The basic pegboard starts at about Nine Bucks for a 4x8 sheet and it goes all the way up to Forty-Five bucks for a hardwood sheet the same size.

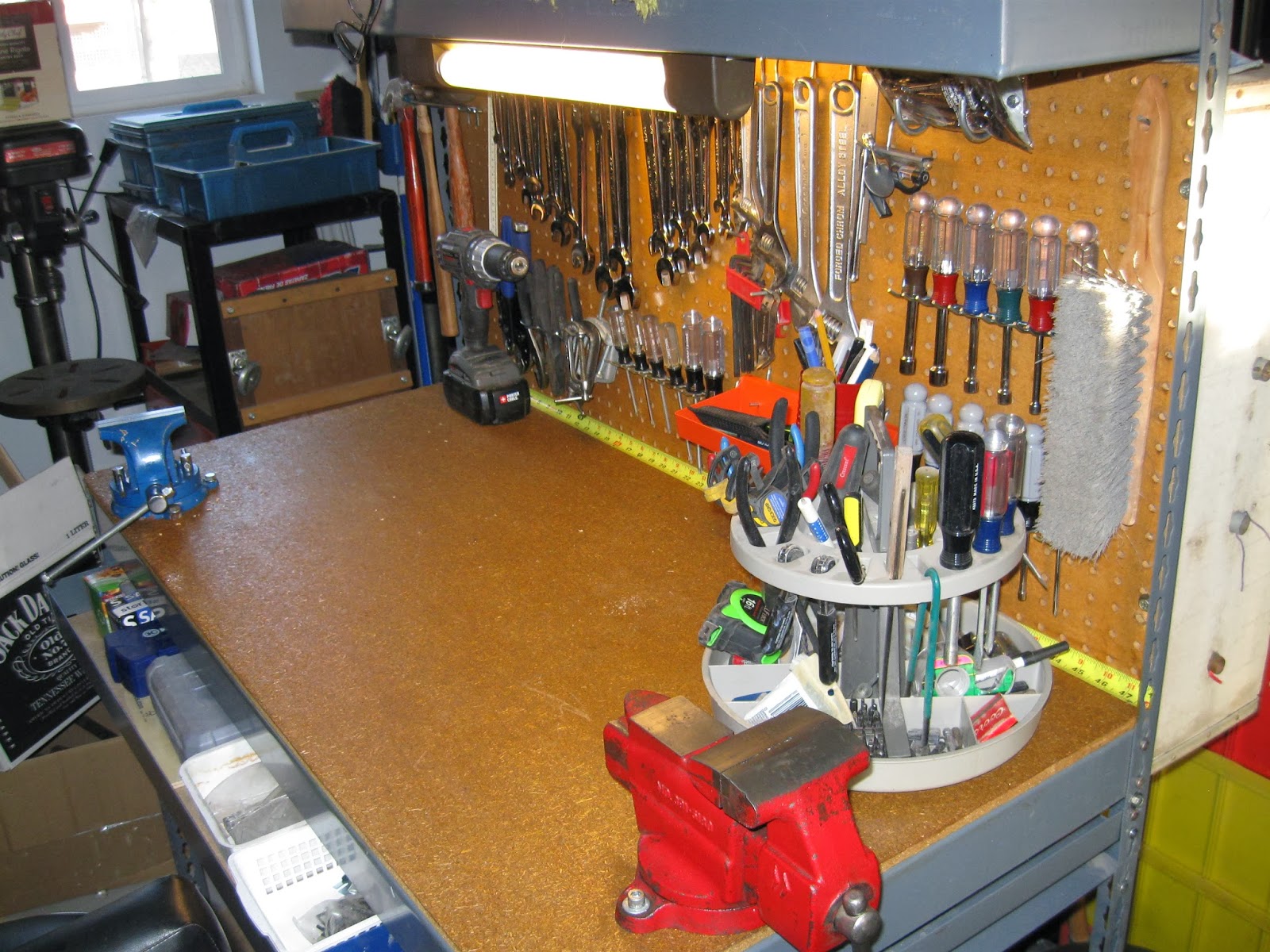

I bought two sheets six or seven years back and hung them in a traditional manner with vertical furring strips mounted at the wall studs to provide space behind the pegboard to mount the hooks. This was necessary due to the finished walls in the garage.

I'm fortunate that I had room for two sheets. Anyway, the furring strips aren't necessary if the garage has bare stud walls.

I also cut and mounted a partial sheet to the back of my project workbench.

This gave me the opportunity to hang my most used tools right where I'm likely to use them.

Pegboard is important to organizing the garage in a creative manner. While scrounging it is an option not to be overlooked, it doesn't turn up that often. Pegboard also rarely turns up at garage sales because once mounted, people almost never take it down. The only scrounging likely to help reduce the cost is to acquire the screws, washers, furring strips and nails.

I bought two sheets six or seven years back and hung them in a traditional manner with vertical furring strips mounted at the wall studs to provide space behind the pegboard to mount the hooks. This was necessary due to the finished walls in the garage.

I'm fortunate that I had room for two sheets. Anyway, the furring strips aren't necessary if the garage has bare stud walls.

I also cut and mounted a partial sheet to the back of my project workbench.

This gave me the opportunity to hang my most used tools right where I'm likely to use them.

Pegboard is important to organizing the garage in a creative manner. While scrounging it is an option not to be overlooked, it doesn't turn up that often. Pegboard also rarely turns up at garage sales because once mounted, people almost never take it down. The only scrounging likely to help reduce the cost is to acquire the screws, washers, furring strips and nails.

Akro-Bins in the Garage

Never overlook the possibility of finding great storage bins at a sale of some sort. In this case I'm referring to Akro-Bins, which come in a variety of shapes and sizes.

Here's two varieties in one. The upper bin organizer is plastic and from the mid Eighties. The lower one is made of metal and probably from the early Eighties or before.

It never hurts to take a picture of the bin part number in case you have missing bins and want to try tracking down replacements.

This is another type of Akro-Bin. These are larger and are stackable.

In this case I placed some of them under the workbench in the picture while the rest are to the left.

The early plastic organizer I bought new years ago. The rest are garage sale finds.

Here's two varieties in one. The upper bin organizer is plastic and from the mid Eighties. The lower one is made of metal and probably from the early Eighties or before.

It never hurts to take a picture of the bin part number in case you have missing bins and want to try tracking down replacements.

This is another type of Akro-Bin. These are larger and are stackable.

In this case I placed some of them under the workbench in the picture while the rest are to the left.

The early plastic organizer I bought new years ago. The rest are garage sale finds.

Wire Spool Box from an Old Wooden Crate

I actually found this wooden wire spool box at a garage sale for the princely sum of a Buck. The wire spools that were already in it have hand written dates form the mid to late Sixties. How cool is that?

One could be made from plywood, screws, some metal strips, pipe, and rubber grommets. I modified the cabinet by cutting some of the holes larger and installing larger grommets to accommodate the 12 and 10 gauge automotive wire seen on the third pipe down. Other than that it got a fresh paint job when I hung it where it sits now.

I really like it as it organizes most of my spooled wire and provides a handy dispenser all in one box.

A Buck! The only way to beat that is to break out the scrounge-O-meter!

One could be made from plywood, screws, some metal strips, pipe, and rubber grommets. I modified the cabinet by cutting some of the holes larger and installing larger grommets to accommodate the 12 and 10 gauge automotive wire seen on the third pipe down. Other than that it got a fresh paint job when I hung it where it sits now.

I really like it as it organizes most of my spooled wire and provides a handy dispenser all in one box.

A Buck! The only way to beat that is to break out the scrounge-O-meter!

Hang that Tool on the Pegboard using a Length of Cord

I needed to hang one of my tire irons on the garage pegboard and in looking at it I decided I didn't want to drill a hole in it. Instead I tied a length of cord into a loop and then secured the loop of cord to the tire iron to hang it with.

If the cord won't stay on the tool, then the cord can be tied differently. This rig seems to be working, so I'll stick with it for now.

If the cord won't stay on the tool, then the cord can be tied differently. This rig seems to be working, so I'll stick with it for now.

Use a Silverware Caddy as a Tool Holder

I thought this idea up years ago and I've used it ever since. I found a silverware caddy I liked and now I use it to hold tools I'm using during a project. It keeps them nice and tidy as long as the tool pile isn't overly huge.

They can be found at garage sales, thrift stores, or at the discount store. You could even purloin the one in the kitchen if you can get away with it.

They can be found at garage sales, thrift stores, or at the discount store. You could even purloin the one in the kitchen if you can get away with it.

Small Lidded Vials Used for Small Parts Storage

I'm sure we've all seen small vials, and various lidded containers floating around in our lives and they do have a use in the garage for storage.

This one is an example. The advantage of the clear ones are the usual being able to quickly identify the contents.

At any rate, free is the watchword when finding storage items for the garage.

This one is an example. The advantage of the clear ones are the usual being able to quickly identify the contents.

At any rate, free is the watchword when finding storage items for the garage.

Baby Food Jars for Storage

Yes, I think it's still possible to get baby food jars in glass containers. The ones I have are pretty old though.

They do have some advantages though. They are smaller than other glass jars, they have lids that reseal decently, and the clear glass makes identifying the contents of the jar pretty easy.

The only real downside is the jar is made of glass making them easy to break if dropped or knocked off the workbench.

Still, they are a decent storage option for free.

They do have some advantages though. They are smaller than other glass jars, they have lids that reseal decently, and the clear glass makes identifying the contents of the jar pretty easy.

The only real downside is the jar is made of glass making them easy to break if dropped or knocked off the workbench.

Still, they are a decent storage option for free.

Peanut Butter Jars for Storage

My sister is quite the peanut butter fanatic. I think she goes through two or three jars a month. Well, I decided to take a look at the jars as a possible storage container in the garage. I ran one through the dishwasher to remove the remaining peanut butter and proceeded to clean up the jar to my standards; namely no labels and no glue.

The peanut butter jars are pretty sturdy and have the decided advantage of being made of clear plastic. The plastic is unlikely to break if the jar is dropped, and being able to see the contents speeds up finding things. I also like that I can label the contents in sharpie. An added bonus, the tops can be color-coded to some extent if you are willing to plan out what the colors mean and be willing to buy different brands of peanut butter to take advantage of the different colored lids.

The peanut butter jars are pretty sturdy and have the decided advantage of being made of clear plastic. The plastic is unlikely to break if the jar is dropped, and being able to see the contents speeds up finding things. I also like that I can label the contents in sharpie. An added bonus, the tops can be color-coded to some extent if you are willing to plan out what the colors mean and be willing to buy different brands of peanut butter to take advantage of the different colored lids.

Plastice Coffee Cans for Storage

At first I lamented the change over of coffee cans from metal to plastic as a loss of a source for storing nuts and bolts.

I got to looking at a can that my sister threw in the trash and realized the plastic ones are at least as good as the metal cans were.

In this case I've got two cans, the larger one has plastic imprinted labels, but the small one had a paper label which I removed along with the glue. The containers are reasonably sturdy, the lids appear to be superior to the old coffee can lids, and it's easy to write the contents on the can in sharpie.

So the venerable coffee can as storage idea still has legs!

I got to looking at a can that my sister threw in the trash and realized the plastic ones are at least as good as the metal cans were.

In this case I've got two cans, the larger one has plastic imprinted labels, but the small one had a paper label which I removed along with the glue. The containers are reasonably sturdy, the lids appear to be superior to the old coffee can lids, and it's easy to write the contents on the can in sharpie.

So the venerable coffee can as storage idea still has legs!

Drilling a Hole in a Tool to hang it on a Peg Board

I needed to place some bicycle tire spoons on the garage pegboard with the rest of my bicycle tools, but they didn't have any holes in them to do so.

Solution: Drill some holes in them!

It's important not to drill holes in a tool that might compromise the strength of the tool. Otherwise, modifying a tool to make it work better in your garage is always an option to think about.

Solution: Drill some holes in them!

So I drilled a hole in the tool in a location that would work and not compromise the strength of the tool.

Here's the tool hanging from the pegboard.It's important not to drill holes in a tool that might compromise the strength of the tool. Otherwise, modifying a tool to make it work better in your garage is always an option to think about.

Magnetic Benchtop Tool Holder made from a Speaker

I saw a novel use of a speaker magnet to make a benchtop tool holder and decided to give it a try.

I had some 1/4 threaded rod lying around along with a doughnut speaker magnet, a stripped down speaker housing, nuts and a few fender washers. After looking it over I decided I needed a couple of 5/16x1 1/4 fender washers to finish the project.

I cut about nine or ten inches of threaded rod, then used washers and nuts to clamp the base to the threaded rod followed by the magnet.

The magnet is strong enough to hold a 6 inch crescent wrench, a Phillips screwdriver and a box cutter knife. I haven't weight tested it, but the idea is to have a magnet that is strong enough to hold a typical small tool without being so strong that I have to hold the stand to extract a tool from it. Of course a good trick to minimize a tip-over is to pull the tool down from the magnet before pulling it away.

I find this more of a conversation piece than something I would really use, but this could change over time so I'll let it occupy space on the bench for now. I suppose the thirty five cents it cost me to make something from raw materials makes it worth the effort.

I had some 1/4 threaded rod lying around along with a doughnut speaker magnet, a stripped down speaker housing, nuts and a few fender washers. After looking it over I decided I needed a couple of 5/16x1 1/4 fender washers to finish the project.

I cut about nine or ten inches of threaded rod, then used washers and nuts to clamp the base to the threaded rod followed by the magnet.

The magnet is strong enough to hold a 6 inch crescent wrench, a Phillips screwdriver and a box cutter knife. I haven't weight tested it, but the idea is to have a magnet that is strong enough to hold a typical small tool without being so strong that I have to hold the stand to extract a tool from it. Of course a good trick to minimize a tip-over is to pull the tool down from the magnet before pulling it away.

I find this more of a conversation piece than something I would really use, but this could change over time so I'll let it occupy space on the bench for now. I suppose the thirty five cents it cost me to make something from raw materials makes it worth the effort.

Zip Lock Bag Storage Ideas

Zip Lock bags can be used to store a variety of items and they have definite advantages over other forms of storage.

First, the clear plastic film makes identifying items in the bag a snap.

Second, the bag collapses down to just the bulk volume of whatever is in it which saves space.

Third, the contents can be written onto the bag in Sharpie further improving identification of the contents.

Fourth, buying them at Dollar Tree or your local discount store keeps the cost per bag down to just a few cents. Never buy the name brand bags as they are always twice as expensive and never more than just a little better quality.

Fifth, the ability to seal the bag tends to keep items in the bag.

Sixth, the ability to seal the bag can protect the contents from drying out (such as rolls of tape).

Seventh, the ability to seal the bag protects the contents from water and dirt.

Eighth, the accommodating nature of the bags makes it easier to organize parts in sub-assembly groups during dis-assembly of some contraption in need of work.

There are a few disadvantages as well.

One, the flimsy variety of the bags do not hold up to things like wads of nails or other sharp objects. Use freezer bags if durability is likely to be an issue.

Two, the bags are not very good at storing heavy objects without the possibility of tearing open.

Three, digging through a pile of bags looking for a specific something is still a pain in the butt.

At any rate, here's a photo of some of the common uses for Zip Lock bags.

It may be a bit hard to see what is in the bags, so in front is a roll of masking tape, then a handful of staples. Next to the staples lies a bag of deck and wood screws, and in the back are some cubes of candle wax.

Let's not forget the variety of sizes available as well. I keep the sandwich and snack sizes in the garage all the time, and swipe the quart and gallon size from the kitchen whenever I need the extra room.

The name of the game is to improve organization in the garage without cutting into the garage budget any more than absolutely necessary. Keeping a couple boxes of these does a fine job and the cost per box can be around a Buck.

First, the clear plastic film makes identifying items in the bag a snap.

Second, the bag collapses down to just the bulk volume of whatever is in it which saves space.

Third, the contents can be written onto the bag in Sharpie further improving identification of the contents.

Fourth, buying them at Dollar Tree or your local discount store keeps the cost per bag down to just a few cents. Never buy the name brand bags as they are always twice as expensive and never more than just a little better quality.

Fifth, the ability to seal the bag tends to keep items in the bag.

Sixth, the ability to seal the bag can protect the contents from drying out (such as rolls of tape).

Seventh, the ability to seal the bag protects the contents from water and dirt.

Eighth, the accommodating nature of the bags makes it easier to organize parts in sub-assembly groups during dis-assembly of some contraption in need of work.

There are a few disadvantages as well.

One, the flimsy variety of the bags do not hold up to things like wads of nails or other sharp objects. Use freezer bags if durability is likely to be an issue.

Two, the bags are not very good at storing heavy objects without the possibility of tearing open.

Three, digging through a pile of bags looking for a specific something is still a pain in the butt.

At any rate, here's a photo of some of the common uses for Zip Lock bags.

It may be a bit hard to see what is in the bags, so in front is a roll of masking tape, then a handful of staples. Next to the staples lies a bag of deck and wood screws, and in the back are some cubes of candle wax.

Let's not forget the variety of sizes available as well. I keep the sandwich and snack sizes in the garage all the time, and swipe the quart and gallon size from the kitchen whenever I need the extra room.

The name of the game is to improve organization in the garage without cutting into the garage budget any more than absolutely necessary. Keeping a couple boxes of these does a fine job and the cost per box can be around a Buck.

Monday, January 6, 2014

Saw Blade Storage

I needed to move my saw blades from their location on the pegboard to somewhere else and noticed that the table saw stand could be a decent location. I already had pegboard pegs so I only needed to drill some holes to mount the pegs and I'm in business.

The result is fairly tolerable, the only problem being it's possible to get nicked on a saw blade tooth if I'm not careful. This hasn't happened yet so I'll let it ride for now.

The bonus is the shop just became a little more efficient and at no monetary cost to me.

The result is fairly tolerable, the only problem being it's possible to get nicked on a saw blade tooth if I'm not careful. This hasn't happened yet so I'll let it ride for now.

The bonus is the shop just became a little more efficient and at no monetary cost to me.

Cardboard Bins Made from Scratch

I needed some bins, and in poking around the web I saw some cardboard ones in a picture. This got me to thinking that the bins would be a good solution for my needs.

I proceeded to investigate the cost and the prices were outside of my budget, plus I had to buy a hundred of them to boot.

This kinda chapped my butt. Chapped Butt Stick is something in short supply around my garage so I set out to sooth the source of irritation.

I sat down and began noodling what I needed to do to make my own. I quickly discovered that it isn't hard to design a cardboard bin, cut the template, and make my own from scrap cardboard.

It's a bit tough to see, but I drew out the tabs and lines for the folds, plus drew the notches I needed to tuck the flaps into. The key in the design is to account for the thickness of the cardboard when working on fold lines. Once I had the hang of it the design went pretty quickly.

I then cut and folded together my prototype. I learned that it is important to hammer the fold lines to get straight folds exactly where I wanted them. I used a straightedge and mallet to do this.

Fits in the drawer exactly the way I wanted it.

So I made five more of them for that drawer. I discovered that there will occasionally be some cutting and trimming to make them fit if an exact fit is required. A decent pair of scissors did the tweaking nicely.

And here's the completed template waiting for me to make more of that design when I need it. I put the dimensions and uses on the template to make it easier to identify should I ever end up with a collection of them.

It took an hour or so to design the first template, then another hour or so to make a second from the template, test and tweak it. After that, cutting and folding one takes about 5-10 minutes depending on the sharpness of your box cutter and your skill. What I do is simply cut the desired bin directly from the template instead of drawing the lines and using a straightedge to make cuts. I did this by placing my railroad rail/anvil on the template to hold it down as I made cuts. It's much quicker and I had no problems with cutting into the template as I made cuts.

Along the way I noticed that Elmer's Glue would work great if extra strength were needed to keep the bin from coming apart. Just apply a daub where the tabs fold together and it should make the bin as permanent as any cardboard box can be.

Ahh, another victory over the garage improvement budget! Total Cost: $0.00

I proceeded to investigate the cost and the prices were outside of my budget, plus I had to buy a hundred of them to boot.

This kinda chapped my butt. Chapped Butt Stick is something in short supply around my garage so I set out to sooth the source of irritation.

I sat down and began noodling what I needed to do to make my own. I quickly discovered that it isn't hard to design a cardboard bin, cut the template, and make my own from scrap cardboard.

It's a bit tough to see, but I drew out the tabs and lines for the folds, plus drew the notches I needed to tuck the flaps into. The key in the design is to account for the thickness of the cardboard when working on fold lines. Once I had the hang of it the design went pretty quickly.

I then cut and folded together my prototype. I learned that it is important to hammer the fold lines to get straight folds exactly where I wanted them. I used a straightedge and mallet to do this.

Fits in the drawer exactly the way I wanted it.

So I made five more of them for that drawer. I discovered that there will occasionally be some cutting and trimming to make them fit if an exact fit is required. A decent pair of scissors did the tweaking nicely.

And here's the completed template waiting for me to make more of that design when I need it. I put the dimensions and uses on the template to make it easier to identify should I ever end up with a collection of them.

It took an hour or so to design the first template, then another hour or so to make a second from the template, test and tweak it. After that, cutting and folding one takes about 5-10 minutes depending on the sharpness of your box cutter and your skill. What I do is simply cut the desired bin directly from the template instead of drawing the lines and using a straightedge to make cuts. I did this by placing my railroad rail/anvil on the template to hold it down as I made cuts. It's much quicker and I had no problems with cutting into the template as I made cuts.

Along the way I noticed that Elmer's Glue would work great if extra strength were needed to keep the bin from coming apart. Just apply a daub where the tabs fold together and it should make the bin as permanent as any cardboard box can be.

Ahh, another victory over the garage improvement budget! Total Cost: $0.00

Friday, January 3, 2014

Garage Made String Dispenser

I found this bobbin of heavy string at a garage sale years ago and I probably would have used more of it if I could ever remember where it is.

I decided to fix this problem by making a string dispenser.

I started by making a bobbin holder.

Then I mounted it to the wall in a location near my project workbench.

I used some eye screws to route the string overhead and drop it down by the workbench.

It might be a little hard to see, but this way I have ready access to the string and the bobbin is out of the way.

I'll never have to look for it again.

I decided to fix this problem by making a string dispenser.

I started by making a bobbin holder.

Then I mounted it to the wall in a location near my project workbench.

I used some eye screws to route the string overhead and drop it down by the workbench.

It might be a little hard to see, but this way I have ready access to the string and the bobbin is out of the way.

I'll never have to look for it again.

Lazy Susan Tool Caddy

I scrounged this lazy Susan type tool caddy at an estate sale a few years ago and I admit it's nice to have the most used tools parked on it. It's sitting on the near end of the bench just behind the red vise.

I don't even know where to buy something like this, although the usual suspects are worth a look.

If I need the space I can easily move it as well.

I don't even know where to buy something like this, although the usual suspects are worth a look.

If I need the space I can easily move it as well.

Hold that Drill Chuck Key with a Speaker Magnet

I have this drill chuck key that I tied a string to so it wouldn't wander off from my bench drill press. Needless to say I wasn't all that impressed with the result.

So I poked around the garage and came up with a speaker magnet to hold it to the drill press with when not in use. Now I realize the string prevented the key from wandering off, but this is really what I had in mind.

It doesn't take much of a magnet to hold a key, but a bit of overkill shouldn't hurt.

More hassle than a string, but it was worth the effort to me.

So I poked around the garage and came up with a speaker magnet to hold it to the drill press with when not in use. Now I realize the string prevented the key from wandering off, but this is really what I had in mind.

It doesn't take much of a magnet to hold a key, but a bit of overkill shouldn't hurt.

More hassle than a string, but it was worth the effort to me.

Cheapie Fluorsecent Light for a Workbench Light

I had a cheap fluorescent light lying around and decided to use it to light up my project workbench. This is the type that is mounted using two screws and has an on/off switch to one side near the light bulb.

Here's the light after mounting it.

And here's what happens when it gets bumped.

I fixed that problem with a third screw to keep it from moving.

I know I've seen these at Walmart, but can't remember the price range. Needless to say, retail value doesn't matter if you managed to scrounge it from somewhere.

Here's the light after mounting it.

And here's what happens when it gets bumped.

I fixed that problem with a third screw to keep it from moving.

I know I've seen these at Walmart, but can't remember the price range. Needless to say, retail value doesn't matter if you managed to scrounge it from somewhere.

Thursday, January 2, 2014

Door Stop Hanger

I spotted a decent trick to manage door stops at Frets.com and decided to adapt it for my own garage.

His version tethers the door stop to a screw in the garage door making it easy to pick up without bending over.

I didn't need this feature so I simply put a loop of 550 cord through the end of the door stop. Then I can hang it from the door knob of the door. This way it's easy to find and right where I need it.

It may not be as handy as the tethered method, but I'm just not quite that lazy to not want to bend over to pick up a block of wood. If I change my mind I can always add a bit of string and do it his way.

His version tethers the door stop to a screw in the garage door making it easy to pick up without bending over.

I didn't need this feature so I simply put a loop of 550 cord through the end of the door stop. Then I can hang it from the door knob of the door. This way it's easy to find and right where I need it.

It may not be as handy as the tethered method, but I'm just not quite that lazy to not want to bend over to pick up a block of wood. If I change my mind I can always add a bit of string and do it his way.

Subscribe to:

Posts (Atom)